GS series rotary pipe dryer / cooling machine

Application process of GS series rotary tube bundle dryer/cooler

GS Series Rotary Tube Bundle Dryer/Cooler is a dryer for processing large-volume materials. It is suitable for drying powdery, granular, lumpy, and paste-like materials mixed with dry materials. It can be divided into three types: direct heating type, conduction heating type, and composite heating type according to the contact mode of the processed material and the cold and heat carrier. The direct heating type is mainly suitable for the drying process of materials with large particles that are not afraid of pollution and cause no environmental pollution. The conduction heating type is suitable for drying materials with a long deceleration drying stage and heat-sensitive materials. The compound heating type is suitable for drying powdery and light materials.

At the same time, this model is also widely used for the thermal decomposition of materials containing crystal water and the high-temperature calcination of special materials. It is now more widely used in the chemical field, including metallurgy, minerals, ceramics, aquatic products, papermaking, food and other industries. Similarly, use excess steam to dry sludge, general garbage, etc.

Application Conditions of GS Series Rotary Tube Bundle Dryer/Cooler

ØMain heat carrier

● Direct or compound heating type

-Flue gas

- hot air

● Conduction heating type

-Steam

-Heat transfer oil

- Hot and cold water

Typical processing materials of GS series rotary tube bundle dryer/cooler

Terephthalic acid, polyvinyl fluoride, polystyrene, polypropylene, corn germ, corn fiber (corn residue), potato fiber, protein powder, feed carrier, fermented feed, fish meal, distilled grains, wood chips, wood chips, rapeseed , Baking powder, beer lees, meat and bone meal, sodium carbonate, basic magnesium carbonate, potassium carbonate, polyvinyl hydrogen, aluminum hydroxide, pentaerythritol, ABS resin, synthetic resin, soda ash calcination, titanium oxide, ammonium nitrate, dolomite, Methionine, lignite, graphite, etc.

Advantages of GS series rotary tube bundle dryer/cooler

● Large production capacity, continuous operation, high evaporation intensity. The evaporation intensity per unit volume of this machine is about 3 times that of a conventional heating tumble dryer.

● High thermal efficiency. It can reach 80%-90%.

● Fewer failures and low equipment maintenance costs.

● Low operating cost and simple operation.

● Long stay time. This adjustment can be arbitrarily changed according to the internal stay and speed.

● Dry at a certain temperature. For indirect heating, the temperature of the heating tube is set according to the steam pressure. This machine is also suitable for drying heat-sensitive materials, and the temperature of general products should be 15-50°C lower than the steam temperature.

● There is little dust in the exhaust. Because it can exhaust under high humidity of 80%-95%, the exhaust volume is small, the wind speed in the dryer is small, the amount of dust is small, and the investment in gas-solid separation equipment is small.

● The system can be operated in a closed condition.

Working principle of GS series rotary tube bundle dryer/cooler

The processed materials are transported to the tube bundle dryer through the feeder, and two to three layers of heating tubes are arranged on the inner circumference of the machine. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal line. The material is added from the higher end. The heat carrier exchanges heat with the material through the heating tube from the lower end. The cylinder is equipped with a copy plate and a material level control device to make the material The movement rate and heat exchange time are precisely controlled to achieve the best heat exchange efficiency. The exhaust gas treatment part is equipped with a dust collector and an induced air device. The induced air generates a slight negative pressure in the equipment to ensure that the secondary steam can be quickly discharged to enhance the drying efficiency. The dust is captured by the dust collector to meet the environmental protection emission requirements. The final qualified products are discharged from the discharge box.

System configuration diagram

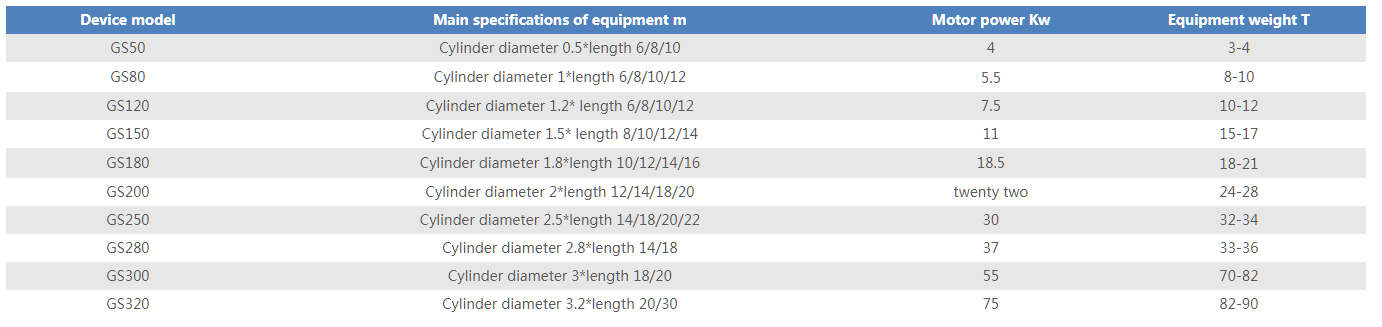

GS Series Rotary Tube Bundle Dryer/Cooler Model

ØEquipment model

Dryer model size comprises heat transfer area of 12 m2 to 1200 m2 heating surface plot. This kind of equipment accepts any customized heat exchange area, and the main specifications and models are as follows.

ØStructural materials

● Carbon steel

● Stainless steel

Equipment applicable conditions

ØHeat transfer medium

—Steam from 0.15MPa to 1.2MPa

—Hot oil to 750°F (400°C)

— Coolant to -40°F (-40°C)

Continuous or batch operation

相关产品

产品留言

Sanmenxia Changshi Machinery Equipment Co., Ltd.

Add:Cizhong Intersection, Huanghe East Road, Hubin District, Sanmenxia City, Henan Province

E-mail:945052081@qq.com

Mobile:13839810833(24h)

Copyright Sanmenxia Changshi Machinery Equipment Co., Ltd.

Powered by www.300.cn 豫ICP备17007575号-1