HC series wedge hollow pulp dryer / cooling machine

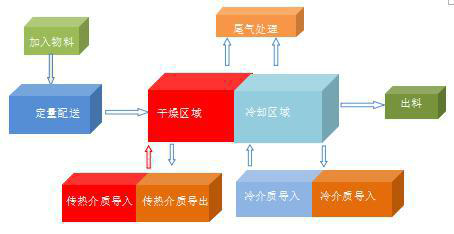

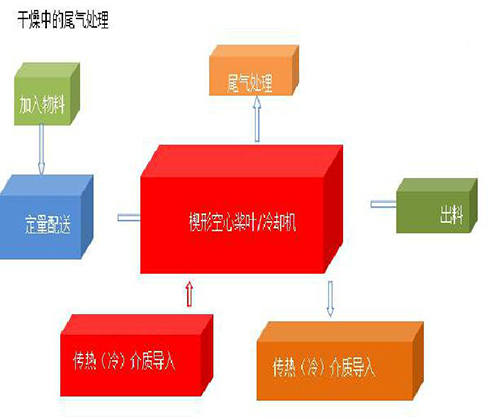

Application process of HC series wedge hollow blade dryer/cooler

With HC series wedge-shaped hollow blade dryer/cooler, powder, granular or paste materials can be heated indirectly (such as: drying) through a heat transfer medium (such as steam, heat transfer oil, water or glycol) Or cool down. We have high-quality blade drying equipment. The unique mixing blade manufacturing technology enables the entire equipment to have excellent heat transfer efficiency and uniform product characteristics. There is no large air flow during the operation of the equipment, which eliminates a series of problems caused by dust. And reduced energy consumption. More than 200 online equipments are sold all over the world. The HC series dryer cooler has been proven to be one of the most efficient indirect heat transfer equipment.

The HC series paddle dryer/cooler is used in the following production processes:

dry

heating

cool down

reaction

melt

Solvent stripping

crystallization

disinfect

Low temperature calcination

Biological fermentation

Fields where the HC series hollow blade dryer has exerted its effectiveness:

Chemistry -drying organic and inorganic compounds, solvent stripping and recovery, thermally controlled reactions, calcination to 750°F (400°C), and cooling.

Petrochemical industry -heating and solvent stripping of materials such as polyethylene and polypropylene, as well as PET crystallization.

Pharmaceuticals -drying and solvent stripping, mixing and drying the mixture, and cooling of the powder.

Food -disinfection, modification of powder, conversion into starch, mixing and heat treatment, cooling of hygroscopic beverage powder, baking or melting.

Metals/Minerals -Drying metal hydroxides, metal oxides and metal ore to extremely low residual moisture content or cooling to powder.

Environmental protection -Reduce treatment costs by drying sludge and by-products or convert waste into valuable by-products.

Advantages of HC series wedge hollow blade dryer/cooler

Øversatility

Paddle dryers/coolers are often used to dry or cool various types of materials. The raw materials can be liquids, slurries, pastes, lumps, granules or powders. The equipment can be designed for continuous operation or intermittent operation according to different working conditions. In the process of processing materials, solid and liquid additives can be introduced into the process in different parts of the equipment according to different process requirements. The design of two partitions in the equipment allows us to control two different operating temperatures, in one machine at the same time to achieve drying/cooling, or heating/cooling, or in a device to achieve multiple temperature reactions.

Øheat transfer rate

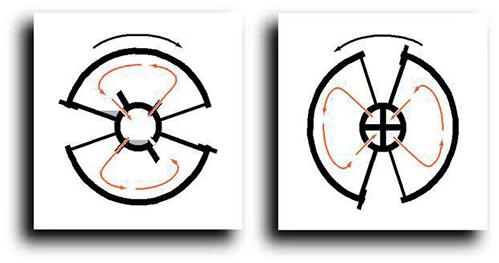

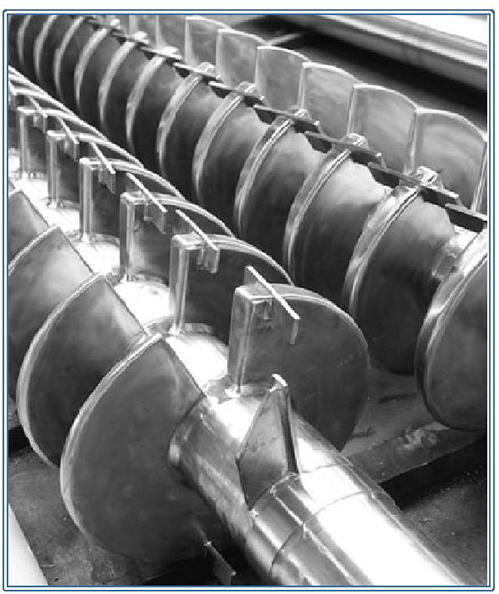

The double counter-rotating blade shaft has a unique intermeshing wedge-shaped blade, so that the material can be uniformly mixed and the heat transfer rate is optimized. The self-cleaning effect of the blade formed by the shear of the blade surface allows the equipment to maintain a high heat transfer rate even when processing viscous materials that may be clogged.

Two partition design of heating and cooling in a single device

Øtemperature and residence time

The local mixing around each blade creates a uniform production condition for the hollow blade dryer. Continuous processing is essentially reverse mixing under the action of plug flow. The product can reach a heat transfer medium temperature as high as 750°F or as low as -40°F (-40°C).

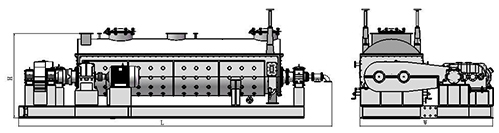

Ødesign

The heat transfer area of the HC series hollow blade dryer/cooler machine occupies a large volume ratio. The most representative is that all its heat transfer areas are covered with materials, so the use efficiency is very high. The demand for high heat transfer rate makes the design of the equipment more compact, thereby reducing the need for space and making the cost of the equipment relatively lower.

Øinternal environmental control

The equipment can be designed to operate in atmospheric, vacuum or pressurized environments. The drying process is usually completed with little or no external exhaust emissions. A small pressure difference created by the induced draft device can separate the volatile steam from the heated material. The steam can be concentrated and kept at a lower temperature. This reduces overall energy requirements and waste gas treatment costs. When volatile organic compounds are present, a vapor-sealed system with inert gas can work. The environmental humidity control in the processor can ensure the processing of hygroscopic materials.

Working principle of HC series wedge hollow blade dryer/cooler

Øheat transfer

The metal shell is used to separate the processing material from the heat transfer medium (steam, oil, water or glycol). When the material comes into contact with low air pressure and agitator, the processed material will be heated or cooled through the heat transfer surface with very high heat transfer efficiency. Heat is directly exchanged or exchanged through material mixing, rather than heat exchange through gas flow. The heat transfer area occupies a large volume ratio because we use hollow blades, shafts and a jacketed shell through which the heat transfer medium flows.

ØSteam

The steam enters the hollow shaft through a rotary joint and is evenly dispersed in all the blades through the capillary heating system. Steam can enter regardless of the direction of the blade. The condensate can be completely discharged through the discharge system after each operation cycle.

Øconduction oil (cooling water)

The liquid enters the hollow shaft through a rotary joint and flows in the hollow blade, regardless of the direction the blade is in, it can be forced into it. The faster liquid flow rate produced by the pipelined flow mode makes the temperature distribution more uniform and the heat transfer coefficient is high.

Øwide range of materials to be conveyed

Paddle dryers/coolers can dry most materials regardless of their handling characteristics. The material return pretreatment is to mix the recycled dry products with the materials so that the materials can be transported more easily. This is a special process. This can have lower costs, operating expenses and maintenance costs, as well as simpler operations.

The material is usually conveyed in the paddle dryer/cooler by displacement. When the material is added from the feeding end, it contacts the heat exchange surface through the stirring action of the agitator. The flowing material generates recoil pressure and mixes with the wedge-shaped blades to push the material to operate around the blades. When high-intensity local agitation and some reverse mixing occur, its overall flow pattern can be summarized as a horizontal plug flow movement at the bottom of the processor.

Uniform mixing makes all materials have the same residence time to ensure uniform product quality. The residence time of the material can be controlled by the height of the overflow stopper or the material removal through the discharge valve at the bottom of the machine. When the processing requires low material residence time or a large volume of material needs to be transported, the blades can be tilted and the processor can also be tilted to increase the transfer rate.

Øshaped hollow blade

Self-cleaning

The double-shaft (or four-shaft) counter-rotating shaft with intermeshing wedge-shaped blades can achieve a high material mixing rate and has a self-cleaning effect, which also optimizes the heat transfer rate. This is all due to the shearing force formed by the wedge-shaped surface of the wedge-shaped blade that rotates when the material is processed.

Wedge blade

The rotating blades cut into the material, and the materials between the blades shear each other to clean the surface of the blades, which helps the blades maintain high heat transfer efficiency.

The wedge-shaped blades and their meshing action create a local circulation for individual particles and materials, increasing the contact area with the heat transfer surface. This continuous mixing also produces a self-cleaning effect and can maintain a high heat transfer rate even when processing viscous materials or materials that undergo a viscous stage during heating, drying and cooling.

The reversing shaft turns the processing material up and moves from the bottom of the shell through the lifting plate on the edge of the tail end of each blade.

Two-axis reverse rotation

Øoperating cost

Easy to operate

-Requires the least attention

—Simple instrument monitoring process

high efficiency

Low exhaust gas

Low maintenance costs

Designed as a simple and durable design with high torque and low operating speed to facilitate maintenance and reduce maintenance costs. No adjustment and maintenance of internal parts. No metal-to-metal contact shafts, seated bearings and driver components are all designed to work in harsh working environments Long service life to ensure long-term equipment integrity.

Øinstallation cost

Compact and concise

Monolithic foundation

Small waste gas treatment system

The removal of the overhead shaft reduces the size requirements of the building.

Complete plant operation

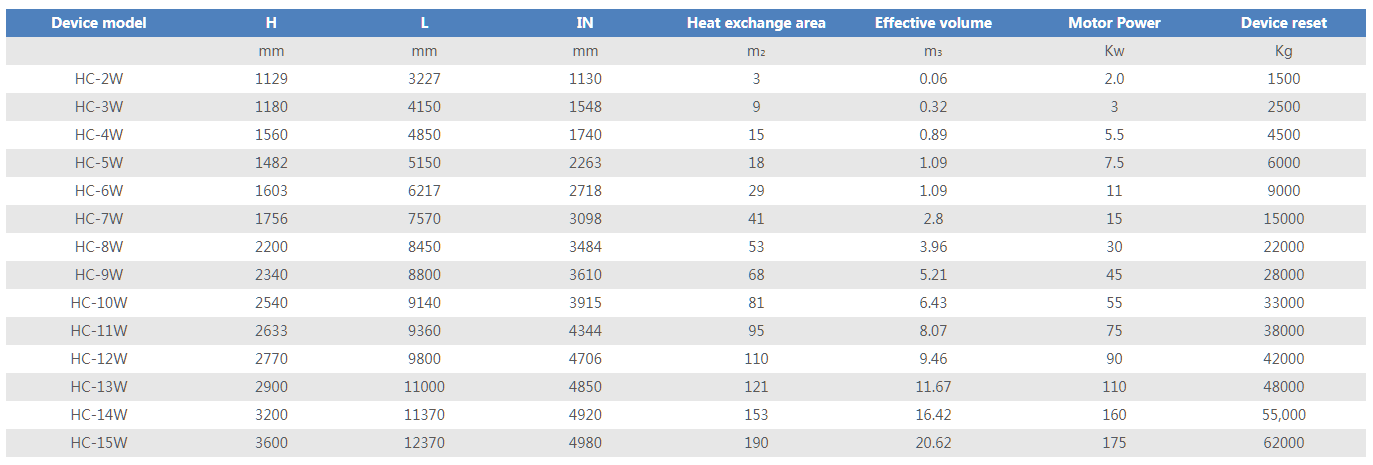

HC series wedge hollow blade dryer/cooler model

Ømodel

The size of the dryer/cooler model ranges from a heat exchange area of 3 square meters to a variety of models with a heat exchange area of more than 300 square meters. The standard models are shown in the table below.

Øpart in contact with the material

● Carbon steel

● Stainless steel

● Nickel-based alloy

● Titanium

● Wear-resistant coating

Øapplicable conditions

Heat transfer medium

—Steam from 0.15MPa to 1.2MPa

--Hot oil to 750°F (400°C)

— Coolant to -40°F (-40°C)

Continuous or batch processing operation under normal pressure, pressure, and vacuum environment provides polished surfaces and welds that meet the requirements of food, medicine and fine chemical application standards.

相关产品

产品留言

Sanmenxia Changshi Machinery Equipment Co., Ltd.

Add:Cizhong Intersection, Huanghe East Road, Hubin District, Sanmenxia City, Henan Province

E-mail:945052081@qq.com

Mobile:13839810833(24h)

Copyright Sanmenxia Changshi Machinery Equipment Co., Ltd.

Powered by www.300.cn 豫ICP备17007575号-1