ZP series vacuum dryer

Engineering application of ZP series vacuum rake dryer

The ZP series vacuum rake dryer is suitable for drying materials in different states and properties. It is especially suitable for the drying of heat-sensitive, easily oxidized or flammable, explosive materials and materials that require solvent recovery and dust pollutants in the drying process. According to different material properties and process requirements, the machine needs to be equipped with dry dust collector, wet dust collector, condenser, condensate tank, vacuum pump, etc. to form a drying unit for operation. At the same time, the machine can also be used for the mixing and heating reaction of solid materials and liquid materials and the mixing and heating of solid materials and solid materials.

Main performance characteristics of ZP series vacuum rake tooth dryer:

The equipment has strong applicability and a wide range of applications. The equipment heats and dries the materials in a vacuum state, which can reduce the vaporization temperature of the solvent. Therefore, the state of the dried material is slurry, paste, granular, powder and fiber. The tax-inclusive rate of these materials after drying can generally reach 0.1% or even lower.

The product quality is good. During the drying process of the material, the interface is constantly updated by the positive and negative rotation of the rake gear shaft, so that the material is heated evenly and avoids overheating of the material.

Easy to operate. The machine is easy to operate, low labor intensity and good operating environment.

The discharge valve is a ball valve with no dead ends in the cylinder, which is convenient for unloading.

No air is involved, the condenser load is small, and the material solvent can be recovered conveniently.

Working principle of ZP series vacuum rake dryer

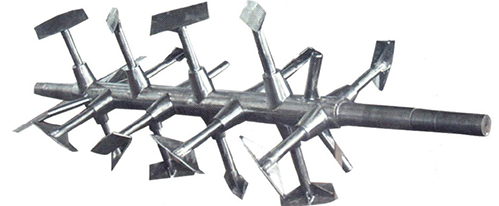

The vacuum rake dryer uses a steam jacket and hollow shaft rake teeth to indirectly heat the material and exhaust it under high vacuum. The material to be dried is added from the feeding port on the top of the shell. Under the stirring of the continuous rotation of the rake teeth, the surface of the material is constantly renewed when the material contacts the shell wall and the rake teeth. The dried material is indirectly heated by steam (or hot water, etc.). The material moisture is vaporized, and the vaporized moisture is pumped away in time by the vacuum pump. Because the operating vacuum is relatively high, generally in the range of 4000-7000Pa, the water vapor pressure on the surface of the dried material is much greater than the water vapor pressure in the evaporation space in the drying shell, which is conducive to the thermal movement of the water molecules of the dried material, which is conducive to the drying. The internal moisture and surface moisture of the material are discharged to achieve the purpose of drying. The machine adopts an automatic reversing device during operation, so that the rotation direction of the rake gear shaft changes the rotation direction of the stirring shaft once every 5-10 minutes, and the stepless speed regulation can be achieved when special requirements are required.

When the main shaft rotates, the rake leaves push the material to both ends. When reversing, the material is raked from both ends to the middle and circulates repeatedly, and the water is taken away from the vacuum pump interface of the feeding port. The dust (solution) entrained in the moisture is collected by the condenser, and the material is discharged from the lower discharge port. Intermittent operation, precision machining of the circular cylinder and the dynamic and static sealing points enable the machine to achieve a high degree of vacuum. Depending on the nature of the material, the inner wall of the cylinder and the stirring shaft can be mirror polished.

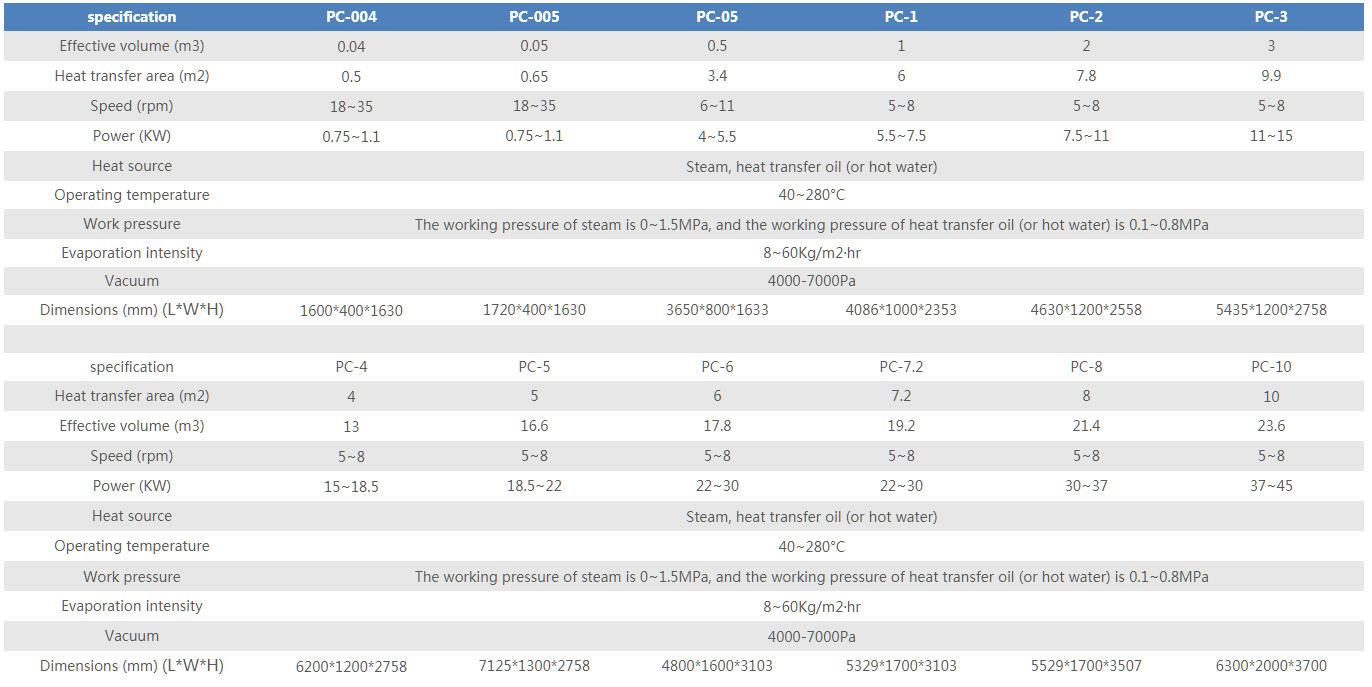

Models of ZP series vacuum rake dryers

相关产品

产品留言

Sanmenxia Changshi Machinery Equipment Co., Ltd.

Add:Cizhong Intersection, Huanghe East Road, Hubin District, Sanmenxia City, Henan Province

E-mail:945052081@qq.com

Mobile:13839810833(24h)

Copyright Sanmenxia Changshi Machinery Equipment Co., Ltd.

Powered by www.300.cn 豫ICP备17007575号-1